NEMA G-10/G-11 Fiberglass Epoxy Laminate Sheets

Grade:

G10/G11 Fiber Reinforced Composite

Colour:

Sheets are supplied in green

Thickness:

0.80mm to 35mm

Subcategory:

Epoxy; Filled/Reinforced Thermoset; Polymer; Thermoset

Description:

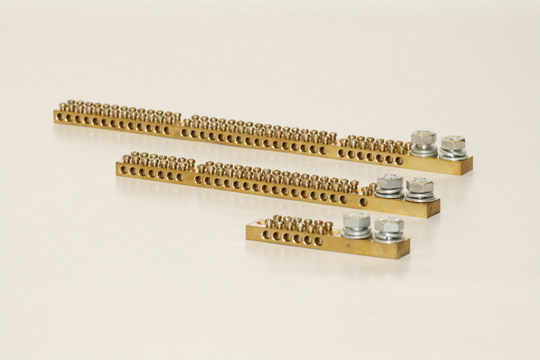

This glass-epoxy laminate is specified for its extremely high strength and high dimensional stability over temperature. G-11 is used for terminal boards, high humidity applications, electrical and electronic test equipment and electric rotor insulation. G-11 is difficult to cut or machine and may require special equipment.

G-10 is slightly Stronger while G-11 is a better insulator and can withstand higher temperature G-11 and similar fibreglass reinforced thermosets are sometimes known as Garolite.